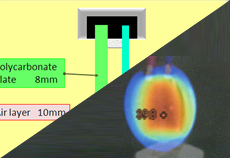

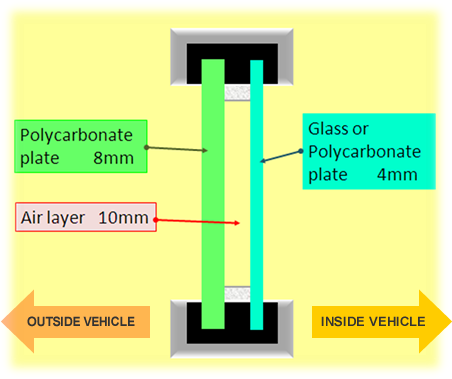

I.G.P (Insulation Glass & Polycarbonate) is a type of window constructed from a layer of polycarbonate incorporated into the glass unit, which results in increased impact resistance, stable product quality, improved resistance to condensation, and reduced installation time.

Outline Diagram

Features

Impact Resistance (To prevent window cracking)

Light Weight

Heat Insulation

Noise Isolation

Transparency (Weather Resistance Discoloration)

Exceptional Air Tightness

Condensation Resistance

Scratch Resistance

Certified Incombustible from Train Materials Fire Test

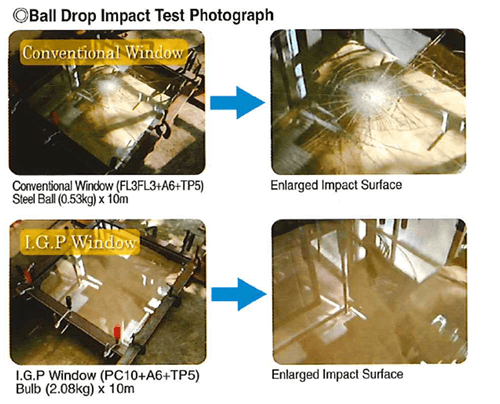

Impact Resistance (Window Crack Prevention)

The external layer is constructed of polycarbonate resin panel, which has an impact strength that is more than 30-times stronger than tempered glass, providing an effective prevention of window cracking. The I.G.P glass shows particularly strong impact resistance against objects that impact from an angle.

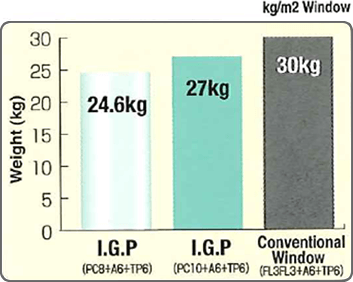

Lightweight

Comparison of Car Window Weight

The polycarbonate resin panel is approximately 1/2 the weight of glass, enabling considerable weight reduction of the car.

Heat Insulation

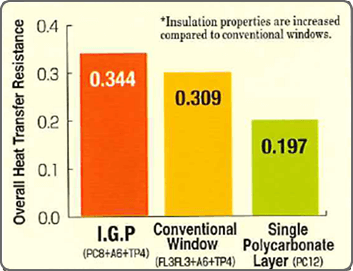

Comparison of Overall Heat Transfer Resistance

(m2・K/W)

Constructed with the polycarbonate resin layer on the exterior, the thermal conductivity of the I.G.P windows is 1/4 that of glass. Additionally, the multi-layered construction provides exceptional resistance to overall heat transfer. Therefore, the I.G.P windows should reduce the need for heating during the winter period. (Contributing to CO2 reduction

Noise Isolation

- 拡大

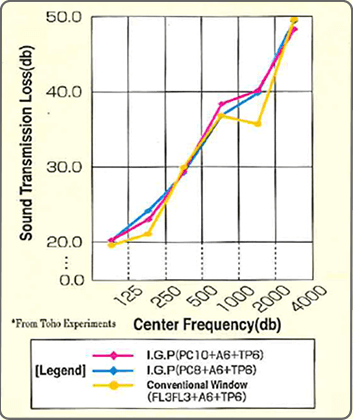

- Comparison of Sound Transmission Loss for Each Type Car Window

The combination of different materials (glass and polycarbonate) not only reduces the weight of the window, it also preserves noise isolation at a higher level than conventional windows.

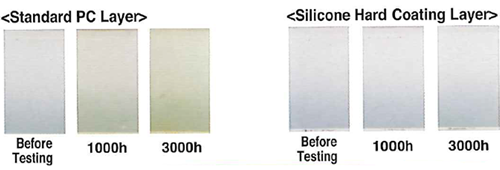

Transparency (Weather Resistance Discoloration

A UV protective treatment is applied to the surface of the polycarbonate making it less likely to discolor compared to standard windows.

- 拡大

- Sunshine Weather Meter Accelerated Weathering Test

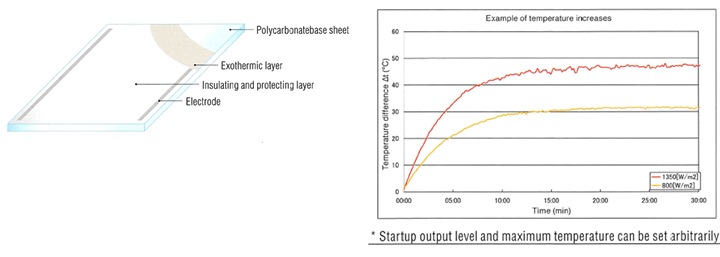

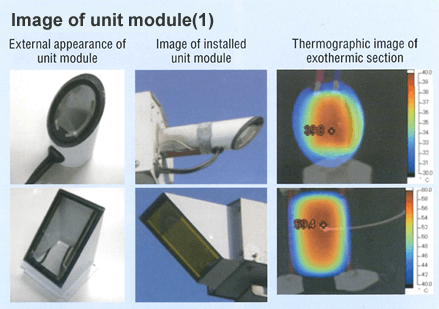

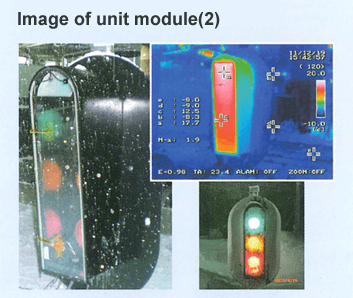

CLEARHEAT is a resin sheet with an exothermic layer surface and a level of transparency that rivals that of polycarbonate resin windows, which have a positive reputation in the railway industry.

Features

Melts snow and prevents condensation

The sheet has been tested as effective in melting ice, even at -30℃

High level of transparency

Parallel light transmittance of 80% or more (550W/m2)

Also allows temperature control

Exothermic properties of △10℃ to △60℃

*Customizable electricity consumption specifications to suit customer requirements. Temperature control is also possible by mounting a temperature sensor.

Visibility

Clear sheet heating without the traditional visible heating wires

Impact resistance

No cracks in 500 g × 5 m falling ball impact tests

Lightweight

Approximately 1/2 the density of glass

Provides heating even across curved surfaces

CLEARHEAT is now available in unit modules to provide heating in a wide range of cold climates.

*The value listed here are measurement values obtained under specific conditions, and are not guaranteed values.